There are several key pieces of information that should be established prior to choosing a trench drain for a brewery application. Load Class, longevity, material, and corrosion resistance are among the most important aspects of this process. Each plays a large role within the project.

The most popular trench drain materials for brewery drainage are vinyl ester, polyester polymer concrete or stainless steel. This is due to their versatile resistance to chemicals and high temperatures. These channel drains are used often in breweries, wineries, cideries and distilleries.

Longevity

One thing to consider when choosing drainage for your brewing application is longevity. The lifespan of the channel, grates, and how long you will remain in the facility are important factors which will help to determine a short or long-term purchase. These details will also assist in pinpointing a material to be used based on cost.

Material

Polymer concrete systems are ideal for many projects due to their low absorption rates and versatility. There are multiple differences between a standard polyester polymer and the vinyl ester polymer concrete systems. While both are polymer concrete-based channels, the variations between the two have a direct impact on a project’s durability, lifespan and cost.

A Polyester-based concrete channel drain is able to withstand temperatures up to 140°F and has resistance to some chemical additives. Whereas, a vinyl ester channel is capable of withstanding not only a higher temperature of 180°F, but also has a high pH level threshold. This provides the vinyl ester channels the ability to resist a larger spectrum of chemicals. This is especially important in brewery drainage applications.

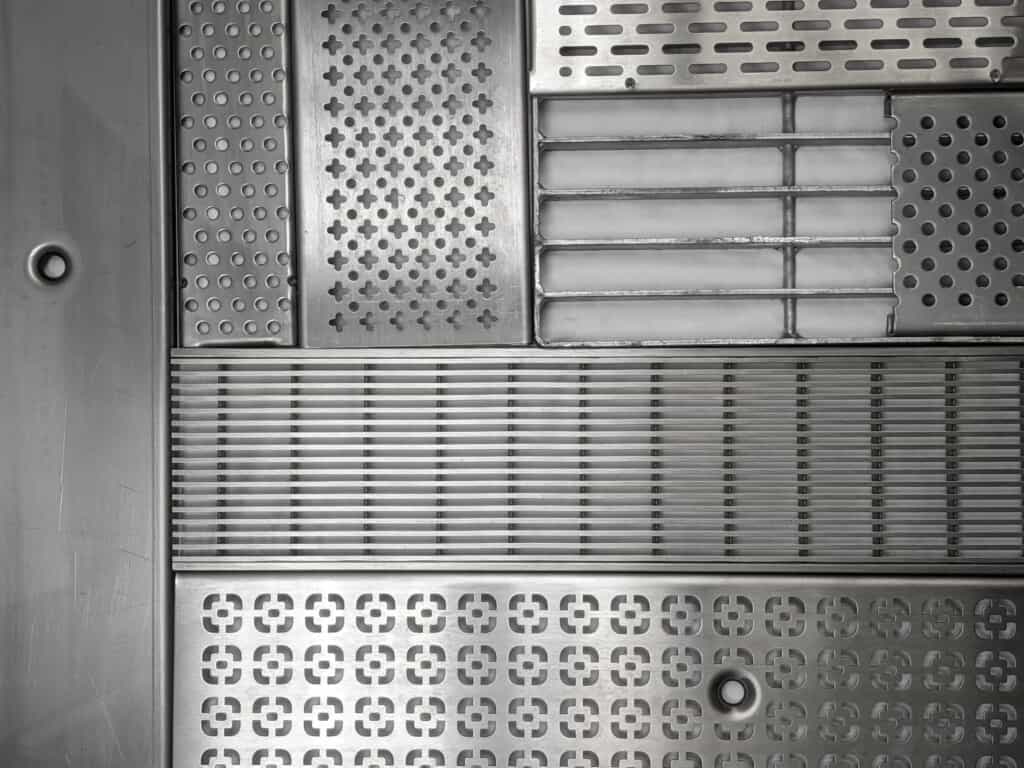

Stainless Steel drainage systems are ideal for the brewing industry, as they have a temperature threshold of 212°F and are often used in food and beverage applications due to its sanitary, durability and lifespan characteristics. These systems are customizable with widths of 6″ and 12″. Request a pricing quote today.

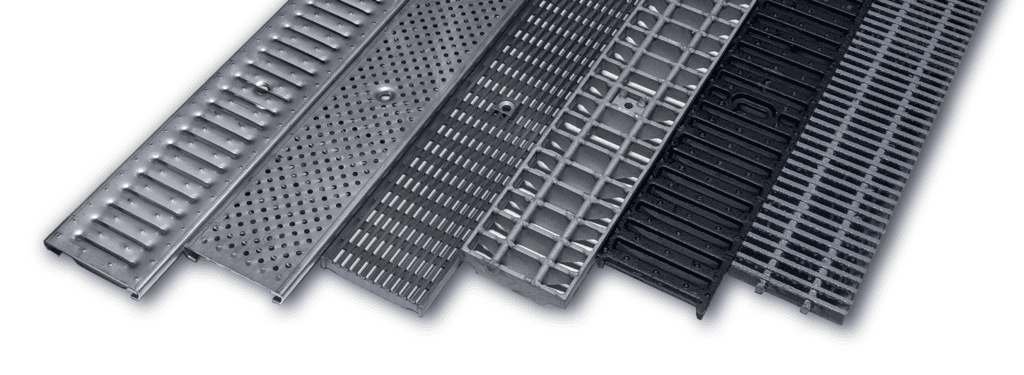

Load Class

Specifying the correct trench drain system for your brewing application is extremely important. Load Class plays a large part in how durable the drainage system is.

First, you must determine what type of traffic will be moving over the grates. This will have a large impact on the life of both the channel drain and grating. For example, if there is any chance of a forklift crossing the system, you will need to install a product that will support the heavy load. If a lesser grating is used, it increases the likelihood of damage due to a partial or full system failure.

Corrosion Resistance

Another facet of choosing a drainage system is grating. Often the same grating material is used as the channel due to the extreme nature of the brewing industry, but is also dependent on the specifics of the application. Each material provides a different aspect to the trench drain.

Stainless steel is great for chemical and heat resistance and gives a nice “clean” look to your operation. It also provides a sanitary option which is regularly required in food grade applications.

Fiberglass is sometimes incorporated with vinyl ester creating a grate and channel combo that is both resistant to high heat and caustic chemicals, as well as being incredibly strong.

Ductile Iron provides savings and strength to the application when cost or Load Class is an issue. However, the ductile iron may not hold up as well due to low chemical resistance and may need replacing often.

Trench Drain Systems is the leading supplier of drainage systems for distilleries, breweries, and micro-breweries throughout the United States. Having worked with over 100 breweries, our experts are ready to help. Trench Drain Systems has an extensive line of trench drain channels, grates, and catch basins, and can help you find cost-effective options for your new and expanding brewery. Contact us for a free quote or for further information on drainage solutions visit TrenchDrain.com or DrainageKits.com

Phone: 610-882-3630

Email: Shop@TrenchDrain.com

Click here for a fast and free quote!