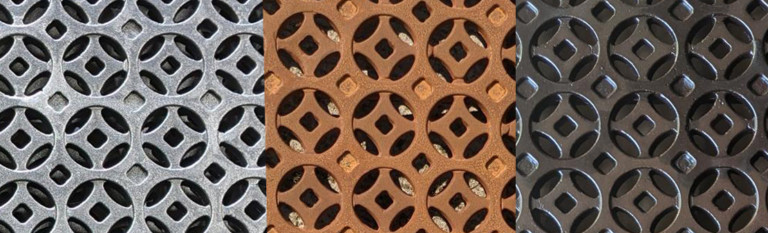

Rust and Cast Iron

Cast iron grates are ideal for many situations and are available in a wide range of shapes and sizes. They are durable and have multiple decorative options. Raw cast iron grates do not retain their natural silver color. In fact, they quickly turn orange with rust when exposed to any form of moisture. This is due to oxygen atoms bonding with iron atoms, resulting in the formation of iron oxides. At first many believe this to be a defect, but in fact, it’s perfectly normal. However, over a period of time cast iron will darken and settle to a rich brown as commonly seen in most parking lots.

Raw

As mentioned, raw cast iron grates are briefly a dull grey or silver before moisture causes a bright orange coarse texture to appear. The iron compounds within the metal react with the water and air in the surrounding environment and oxidize, which we see as rust (iron oxide or hydrated oxide). This is a natural oxidation process that all cast iron grates go through.

Cast iron grates eventually turn to a rich shade of brown over an extended period. The hue and timing of the final coloration depend on a few factors. The first is the chemical makeup of the iron used. Grates that were cast with a mixture containing a high content of iron will end up with a reddish amber shade of brown while more evenly mixed casts will become a tone similar to chocolate. Other factors are regional and environmental. Areas where saltwater spray occurs may have an impact on the transition as well as grates that have exposure to drainage with harsh chemicals. Due to these factors, the timing of the change can be as soon as six months or longer than two years. It is something that cannot be easily predicted.

Lifespan Factors

A grate’s conditions highly affect its stability and longevity. After the rapid rusting process has ebbed, a layer of iron-oxide silicate is created which has become passive (not actively rusting) caused by the presence of silicon within the iron. This allows the material to be less affected or corroded over time by its environment. If this layer is chipped or broken away then the oxidation process continues causing the iron to weaken. Each oxidation process varies depending on the grate’s surroundings and the amount of traffic it is exposed to. It can take at least two years for the rusting process to taper off and settle to the darker natural patina.

Several factors can influence the endurance of cast iron grates. Grates within a building, such as a warehouse or a vehicle maintenance bay, may experience a longer life without vulnerabilities caused by the elements. However, these same grates could experience accelerated deterioration caused by drainage runoff that involves a consistent flow of harsh chemicals. Another consideration is the grate’s exposure to environmental and regional conditions with varying rainfall volume. Grates installed along coastal areas may see an increased transformation rate due to their constant contact with saltwater.

Baked on Oil Finish

If you are short on time and wish to have the patina without the long wait, a baked-on oil finish may be your answer. This is a specialized option that is offered through Trench Drain Systems. By putting the grate through a series of processes, it accelerates the oxidization and creates an even coloring throughout resulting in a beautifully rich amber-brown grate. This process is offered on most of our cast iron grates. This finish is particularly helpful to avoid rust stains on newly poured concrete.

Choosing cast iron for your application may solve many of your drainage problems. Having bright orange grates doesn’t have to be one of them. With the Baked-on Oil Finish, the grates will still minutely rust, but not to the same extreme as a raw cast iron grate. This process allows you to have more control over your grate’s aging process and provides a long-term solution to oxidizing grates.

The experts at TDS can help you find the right drains to fit your plan and budget. Contact us for a free quote or for further information on drainage solutions visit TrenchDrain.com or DrainageKits.com

Phone: 610-882-3630

Email: sh**@tr*********.com